Escalators play a key role in vertical transport within airports, stations, shopping centres and other buildings with large transport flows. If an escalator stops moving due to a malfunction, it must be repaired as soon as possible. But what if the escalator control needs to be replaced? “Until now, it would take eight to twelve weeks to have the control replaced,” says Stefan van der Zee, director of Pro-Engineering. “With our new universal escalator control, suitable for the modernization of all escalator brands, everything is ready within about a week and a half.” Pro-Engineering relied on the expertise of Liftinstituut for the safety certification.

Complete escalator control

Pro-Engineering originated from the company Electronic Repair Rotterdam, which repairs consumer electronics on behalf of Sony, LG and Samsung, and others. “It all started with an escalator manufacturer asking us if we could urgently repair an escalator circuit board. Due to our speed, we were contacted by more and more customers, also to repair faults on location.”

“What we noted time and again is that much of the escalator equipment in the Netherlands is outdated. The same goes for escalator controls, many of which no longer meet the standards. At one point, a customer called us for such a control. He could not have new escalators installed because they were part of a shopping mall that is open all year round. So our engineers got to work on the development and came up with a complete escalator control that can be used universally. In other words, one control that can be used for all types of escalators. This makes us unique.”

Functional safety at SIL2 level

Functional safety at SIL2 level

In order to guarantee safety and minimize liability risks, Van der Zee opted for a certification process by Liftinstituut: “It is a globally known and reputable certification organization focused fully on escalators and lifts. They are well aware of all standards and the latest technology. I have to admit that at first we found them rather strict, but when you see how they contributed to the necessary safety, we are very happy with that.”

“Furthermore, the certification experts of Liftinstituut also provided good guidance on all complex legislation, standards and risk analyses. As a result, our escalator control overall meets the requirements of SIL2.”

In addition to the basic version, we have also developed a version of the escalator control with energy-saving mode. Remote monitoring is also available as an option. “This gives our customers and us real-time insight into the status, malfunctions and the maintenance status of each escalator.”

From escalator control to lift control

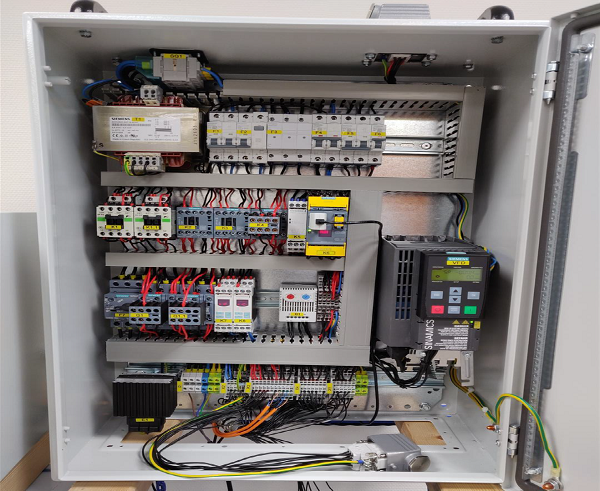

Pro-Engineering is also currently working internationally to promote its universal escalator control. At the same time, the engineers are already focusing on a new product: a lift control. “We have already signed framework agreements with several lift manufacturers. Modernization and lift malfunctions often require quick solutions. The repair of a circuit board, for instance. Their own production facilities often need weeks, while customers demand speedy solutions. Taking a lift out of service for a prolonged period of time is not an option.”

Van der Zee will gladly renew the collaboration with Liftinstituut again for the certification of the lift control: “Last time, we were already in the middle of the design process when Liftinstituut joined us. Due to the standards, which we, as a very practical company, were completely unfamiliar with - we had to start almost from scratch. This time, the certification experts will already join us at the drawing board. This ensures we can guarantee the safety of our products right from the design phase.”

Van der Zee will gladly renew the collaboration with Liftinstituut again for the certification of the lift control: “Last time, we were already in the middle of the design process when Liftinstituut joined us. Due to the standards, which we, as a very practical company, were completely unfamiliar with - we had to start almost from scratch. This time, the certification experts will already join us at the drawing board. This ensures we can guarantee the safety of our products right from the design phase.”